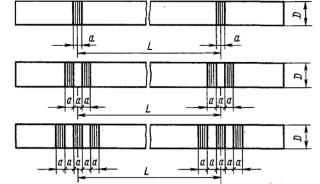

Fig. 1

Based on GOST 14202-69. This page is not the original document. Translation may be inaccurate.

By the decision of the Committee of Standards, Measures and Measuring Devices attached to the Council of Ministers of the USSR of February 7, 1969 No. 168, the introduction period was established from 01.01.71.

1. This standard covers identification markings, warning signs and marking plates of pipelines (including connecting parts, fittings and insulation) on the designed, newly constructed, reconstructed and existing industrial enterprises inside buildings, on outdoor installations and communications located on overpasses and in underground channels to quickly determine the contents of pipelines and to facilitate the management of production processes, as well as to ensure work safety.

The standard does not apply to the identification of pipes and conduits with electrical wiring.

2. The following ten enlarged groups of substances transported by pipelines are installed:

3. Color marking and numerical designation of enlarged pipelines groups should correspond to those indicated in Table 1.

| Table 1 | ||

| Transported substance | Samples and color name of marking | |

| Group numeric designation | Name | |

| 1 | Water | Green |

| 2 | Steam | Red |

| 3 | Air | Blue |

| 4 | Combustible gases | Yellow |

| 5 | Non-combustible gases | |

| 6 | Acids | Orange |

| 7 | Caustic | Purple |

| 8 | Flammable liquids | Brown |

| 9 | Non-flammable liquids | |

| 10 | Other substances | Gray |

4. The characteristics of the colors of the identification coloring shall comply with those specified in Annex 1.

5. Fire-fighting pipelines irrespective of their contents (water, foam, fire extinguishing steam, etc.), sprinkler and deluge systems in the areas of shut-off and control valves and in the places of connection of hoses and other devices for extinguishing the fire must be painted red (signal) .

If it is necessary to specify the contents of fire-fighting pipelines, they can be additionally designated by means of marking plates painted in corresponding distinctive colors.

6. The identification coloring of pipelines should be made continuous throughout the surface of communications or in separate areas.

The method of performing the identification coloring should be selected depending on the location of the pipelines, their length, diameter, the number of co-located lines, safety and industrial sanitation requirements, lighting conditions and visibility of pipelines for maintenance personnel and a general architectural solution.

Painting of pipelines by sections is recommended to be carried out in shops with a large number and length of communications, and also in those cases where the working conditions, due to increased requirements for color reproduction and the nature of the architectural solution of the interior, undesirable concentration of bright colors.

Identification color across the surface of pipelines it is recommended to apply at a small length and a relatively small number of communications, if it does not impair the conditions of work in the workshops.

On external installations, the identification of the entire surface is recommended only in cases where it does not cause deterioration of operating conditions due to exposure to solar radiation communications.

7. When applying the identification coloring to the pipelines inside the production premises, it is recommended to paint the rest of the communications surface in the color of the walls, partitions, ceilings and other elements of the interiors against which the pipelines are located. At the same time, it is not allowed to paint the pipelines between the areas of identification color adopted for other enlarged groups of substances.

8. When applying the identification of the areas to pipelines outside the buildings, the rest of the communication surface is recommended to be painted in colors that help reduce the thermal effects of solar radiation on the pipelines.

9. When laying communications in non-flow channels and with non-channel communication, areas of identification coloring on pipelines should be applied within the chambers and inspection wells.

10. Sites of identification coloring should be applied taking into account local conditions at the most important points of communications (at branches, at joints, flanges, at sampling points and instrumentation, in places of pipelines passing through walls, partitions, ceilings, at the inputs and outputs from production buildings and .p.) no less than 10 m inside the production premises and at outdoor installations and 30 - 60 m on the outer main routes.

11. The width of the areas of the identification coloring should be taken depending on the outer diameter of the pipelines (taking into account insulation):

With a greater number of parallel communication lines, the areas of identification on all pipelines are recommended to take the same width and apply them at the same intervals.

With large pipe diameters, the areas of identification coloring may be applied in the form of strips with a height of not less than 1/4 of the circumference of the pipeline.

12. To designate the most hazardous by the properties of transported substances on the pipelines, apply warning colored rings.

The identification color for the warning rings must be as specified in Table 2.

| Table 2 | ||

| Samples of signal colors | Name of signal colors | Property of transported substance |

| Red | Highly flammable and explosive | |

| Yellow | Danger or harmfulness (toxicity, the ability to cause suffocation, thermal or chemical burns, radioactivity, high pressure or deep vacuum, etc.) | |

| Green | Safety or neutrality | |

| Notes. 1. When applying rings of yellow color on the marking color of pipelines of gases and acids, the rings must have black edges with a width of at least 10 mm. 2. When applying rings of green color on the marking color of water pipelines, the rings must have white edges with a width of at least 10 mm. | ||

13. In cases where the substance simultaneously possesses several hazardous properties, designated by different colors, several colors must be applied to the pipelines at the same time.

On vacuum pipelines, except for the distinctive color, it is necessary to give the inscription "vacuum".

14. By the degree of danger to life and health of people or the operation of an enterprise, substances transported through pipelines must be divided into three groups, denoted by the corresponding number of warning rings in accordance with Table 3.

15. The characteristics of the signal colors shall be as specified in Annex 2.

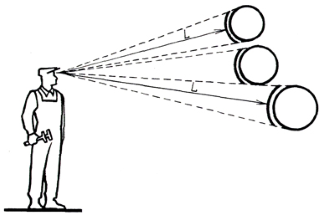

16. The width of the warning rings and the distance between them should be adopted depending on the outer diameter of the pipelines in accordance with Fig. 1 and Table 4.

17. With a large number of parallel communication lines, the warning rings on all pipelines should be of the same width and applied at the same intervals.

18. Gas discharge lines and air blowing, depending on their contents, should have an identification color set for the symbol of enlarged groups, with winding transverse rings of the corresponding signal color.

19. Warning signs should be used in addition to color warning rings in order to designate pipelines that are particularly hazardous to human health and life or the operation of the enterprise, and if it is necessary to specify the hazard.

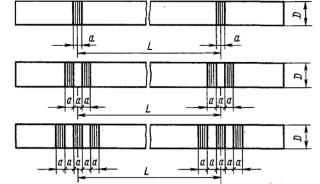

20. The following substances should be indicated by warning signs: toxic, flammable, explosive, radioactive, as well as other dangerous contents of pipelines (for example, substances that present a hazard during spraying, etc.).

21. The warning signs must be in the form of a triangle. Images should be black on a yellow background.

| Table 3 | ||||

| Gr | Num | Transported substance | Pressure, kgf/cm² | Tempe |

| 1 | One | Superheated steam | Up to 22 | 250 to 350 |

| Hot water, saturated steam | 16 to 80 | Over 120 | ||

| Superheated and saturated steam, hot water | 1 to 16 | 120 to 250 | ||

| Combustible (including liquefied and active gases, flammable and combustible liquids) | Up to 25 | -70 to 250 | ||

| Non-flammable liquids and vapors, inert gases | Up to 64 | -70 to 350 | ||

| 2 | Two | Superheated steam | Up to 39 | 350 to 450 |

| Hot water, saturated steam | 80 to 184 | Over 120 | ||

| Products with toxic properties (except potent poisonous substances and fuming acids) | Up to 16 | -70 to 350 | ||

| Combustible (including liquefied and active gases, flammable and combustible liquids) | 25 to 64 | 250 to 350; -70 to 0 | ||

| Non-flammable liquids and vapors, inert gases | 64 to 100 | 340 to 450; -70 to 0 | ||

| 3 | Three | Superheated steam | Regardless of pressure | 450 to 660 |

| Hot water, saturated steam | Over 184 | Over 120 | ||

| Strongly-acting poisonous substances and fuming acids | Regardless of pressure | -70 to 700 | ||

| Other products with toxic properties | Over 16 | -70 to 700 | ||

| Combustible (including liquefied and active gases, flammable and combustible liquids) | Regardless of pressure | 350 to 750 | ||

| Non-flammable liquids and vapors, inert gases | Regardless of pressure | 450 to 700 | ||

| Note. For substances that are hazardous by properties or a combination of properties not listed in this table, hazard groups should be established in consultation with government agencies. | ||||

Fig. 1

| Table 4 | ||

| Outer diameter (with insulation) D, mm | L, mm | a, mm |

| Up to 80 | 2000 | 40 |

| 81 to 160 | 3000 | 50 |

| 161 to 300 | 4000 | 70 |

| Over 300 | 6000 | 100 |

22. The image of warning signs should be taken in accordance with Fig. 2 and Table 5.

23. In those cases when the change in the shade of the distinctive colors can occur from the influence of aggressive flowing substances, the pipelines should be marked with the help of marking plates.

24. Marking plates should be used for additional identification of the type of substances and their parameters (temperature, pressure, etc.) required by the operating conditions.

Marking plates on pipelines or on the surface of structures to which pipelines are attached must be marked with alphabetic or digital inscriptions.

25. Inscriptions on the shields of pipelines must be carried clear, well legible font and shall not contain unnecessary data maloupotrebimyh terms and obscure acronyms. The font for inscriptions is recommended to be accepted in accordance with GOST 10807-78.

Fig. 2

| Table 5 | |

| Size options | a, mm |

| 1 | 26 |

| 2 | 52 |

| 3 | 74 |

| 4 | 105 |

| 5 | 148 |

It is allowed to designate the substance type by means of numbers in accordance with Appendix 3.

The designation of the substance type by means of chemical formulas is not allowed.

26. The direction of flow of substances transported through pipelines should be indicated by the sharp end of the marking plates or arrows applied directly to the pipelines.

The shape and size of the arrows should correspond to the shape and size of the marking plates.

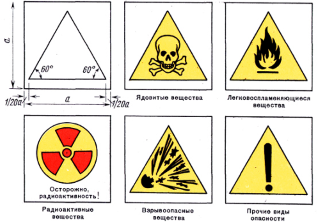

27. Marking plates must be of four types:

28. The dimensions of the marking plates must correspond to those indicated in Fig. 3 and in Table 6.

29. Variants of the sizes of marking plates, inscriptions and warning signs should be applied mainly:

1 - in laboratories;

2 and 3 - in industrial premises;

4 and 5 - on outdoor installations and external trunk routes.

30. Warning signs when attaching them to pipelines should be put together with marking plates.

Fig. 3

| Table 6 | ||||

| Size options | a, mm | b, mm | Height of letters h, mm | |

| one line | two lines | |||

| 1 | 26 | 74 | 19 | - |

| 2 | 52 | 148 | 32 | 19 |

| 3 | 74 | 210 | 50 | 25 |

| 4 | 105 | 297 | 63 | 32 |

| 5 | 148 | 420 | 90 | 50 |

31. The height of the markings on the pipelines should be taken depending on the outer diameter of the pipeline in accordance with Fig. 4 and Table 7.

The color of the markings and arrows indicating the direction of the flow applied to the pipelines and marking plates must be white or black, taking into account the greatest contrast with the main color of the pipelines.

The color of the inscriptions when deposited on the background of an identification color is:

white - on a green, red and brown background;

black - on blue, yellow, orange, purple and gray background.

32. The size of the marking plates, inscriptions and warning signs must be selected depending on the distance from which they should be perceived by the personnel associated with the operation of the pipelines, in accordance with Fig. 5 and Table 8.

33. Paint coatings for identification marking, marking plates and warning signs should be carried out in accordance with the applicable standards for paint and varnish materials and coatings, depending on the material of the pipelines or the insulation that protects them and the operating conditions, as well as the cost of paint and varnish coatings and the technology of their application.

34. Paintwork materials used for identification marking, marking plates and warning signs must meet the requirements of the relevant standards, as well as technical documentation approved in accordance with the established procedure.

35. When preparing surfaces for painting, applying and drying paintwork, the safety rules and fire-fighting measures prescribed by the current fire regulations and rules must be observed.

| Table 7 | |||

| Size options | Outer diameter D, mm | Height of letters h, mm | |

| one line | two lines | ||

| 1 | Up to 30 | 19 | - |

| 2 | 81 to 160 | 32 | 19 |

| 3 | 161 to 220 | 50 | 25 |

| 4 | 221 to 300 | 63 | 32 |

| 5 | Over 300 | 90 | 50 |

36. In the heated and ventilated industrial premises without aggressive media, it is recommended to perform the identification of pipelines, marking plates and warning signs with pentaphthalic enamels of PF-115 grades in accordance with GOST 6465-76, PF-133 according to GOST 926-82 and other brands according to technical documentation approved in the established order.

It is recommended to paint the fireproof pipelines and equipment with red enamel according to the technical documentation approved in the established order.

37. The identification and signal colors are allowed to be accepted in accordance with the following standards of the card index of color standards: green N 343 - 344; Red N 10 - 11; blue N 423 - 424; yellow N 205 - 206; orange N 101 - 102; purple N 505 - 506; brown N 647 - 648; gray N 894 - 895. Necessary shades of purple and brown in accordance with the samples of Table. 1 can be obtained by adding a white dye.

38. The identification coloring of pipelines and the color finishing of marking plates and warning signs should be periodically renewed in order to ensure a clear visibility of colors, images and inscriptions. The color should be smooth, without streaks, wrinkles, stains and should not flake.

39. Marking plates, inscriptions and warning signs should be located taking into account local conditions at the most important points of communication (at branches, at connection points, at sampling points, at valves, gate valves, control devices, in places of passage of pipelines through walls, partitions , overlapping, on inputs and outputs from production buildings, etc.).

Marking plates, warning signs and inscriptions on pipelines should be located in well-lit areas or illuminated to ensure their clear visibility, while the light sources should not cover the images and inscriptions, and dazzle the staff when observing them.

Fig. 5

| Table 8 | |

| Distance from observer L in m | Recommended size options for plates, inscriptions and signs |

| Up to 6 | 1 |

| 6 to 12 | 2 |

| 12 to 18 | 3 |

| 18 to 24 | 4 |

| Over 24 | 5 |

The lowest illumination at responsible points of communication with the placement of marking plates, inscriptions and warning signs in them is recommended to take 150 lux with fluorescent lamps and 50 lux with incandescent lamps.

40. In all workplaces where pipelines are available, schemes for identifying the color of communications with decoding of distinctive colors, warning signs and digital signs taken for marking the pipelines should be hung on well-visible locations.

|

|